Specifiers are increasingly opting for materials with a lower Light Reflectance Value (LRV) for exterior applications. This article will provide a closer look at LRV, why it matters, and how Covet Ever Art Wood® aluminium cladding battens can provide a highly versatile, low-LRV option for external façade applications.

Colour and surface properties of cladding, building materials or paint are key factors in any architectural project. Choosing contrasting and complementary colours, opting for gloss or matte finishes, smooth or textured surfaces - designers and specifiers must carefully consider each material they select to ensure it will be fit for purpose, durable and visually pleasing. A key concern in this regard is Light Reflectance Value (LRV). Put simply, LRV is a number value for contrast; a measure of how much usable light a certain material will reflect.

What is LRV and Why is it Important?

Light Reflectance Value (LRV) is a measurement of the light that is reflected from a surface when illuminated by a light source. It is expressed as a number (or percentage value) of 1-100; the higher the number, the more reflective the surface. In theory an LRV of 0 is an absolute black, and 100 a perfectly reflective white - however in real terms these values don’t exist; a very dark black would have LRV around 5 and a very reflective white would be around 85.

LRV is useful in guiding designers and specifiers in a range of applications. It has long been a concern for interior designers trying to ensure that spaces are adequately lit. An interior designer would use the LRV of the paint in the room to determine what sort of lighting would be required. LRV also plays an incredibly important role in designing accessible spaces. As a measure of contrast, LRV can be used to determine appropriate differentiation between materials in designing for people with vision impairment. Having light surfaces adjacent to dark surfaces makes spaces easier to navigate.

LRV also acts as an important safety guideline as a measure of glare or reflectivity for exterior finishings. This is becoming increasingly common in urban settings where a maximum LRV for external façades on new developments is specified to minimise glare for motorists and pedestrians. In Australia, City of Sydney council was first to codify a reflectivity limit for building exteriors of 20% (defined as the percentage solar reflection when light strikes and reflects perpendicular to the façade element), a measure which has subsequently been adopted by many local councils in the Sydney and Melbourne metropolitan areas.

Measuring LRV

Accurately measuring LRV can be a tricky process - bear in mind that the perceived reflectivity of a surface may change based on the angle of light it’s being subjected to, and the angle of the receiver in relation to both the surface and the light. Furthermore, when measuring textured surfaces, the reflectivity can be different depending on which part of the sample is being measured. For this reason, one of the most common tests for determining LRV, BS 8493-2008 + A1-2010, specifies the use of a spherical spectrometer in the test. The spherical spectrometer allows accurate measurements from almost infinite angles of reflection, and is used at no fewer than nine points across a sample of at least 450mm x 450mm (a bigger sample would be measured at more points) during the test. This provides a wide data set from which an accurate LRV can be determined.

It is becoming increasingly common in urban settings where a maximum LRV for external façades on new developments is specified to minimise glare for motorists and pedestrians.

LRV and Covet Ever Art Wood®

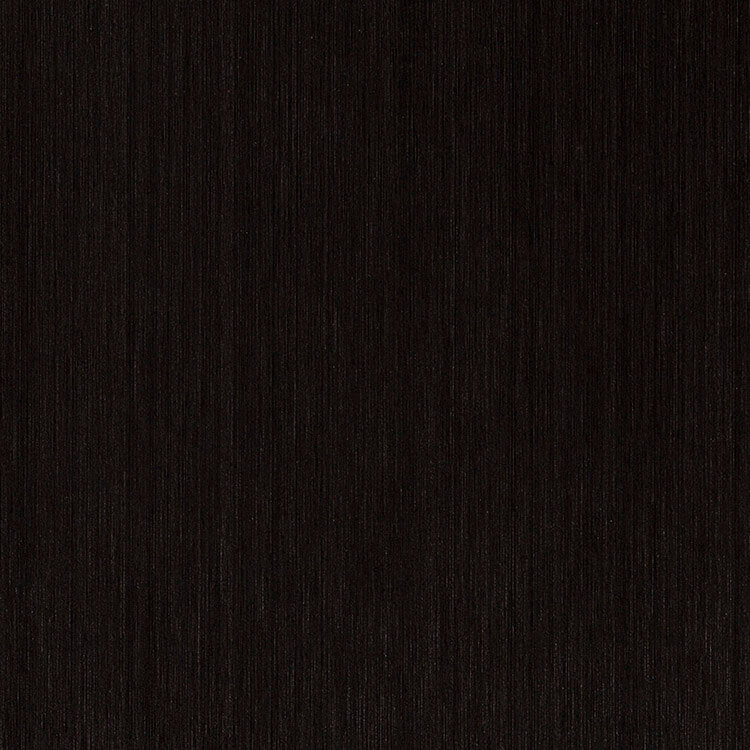

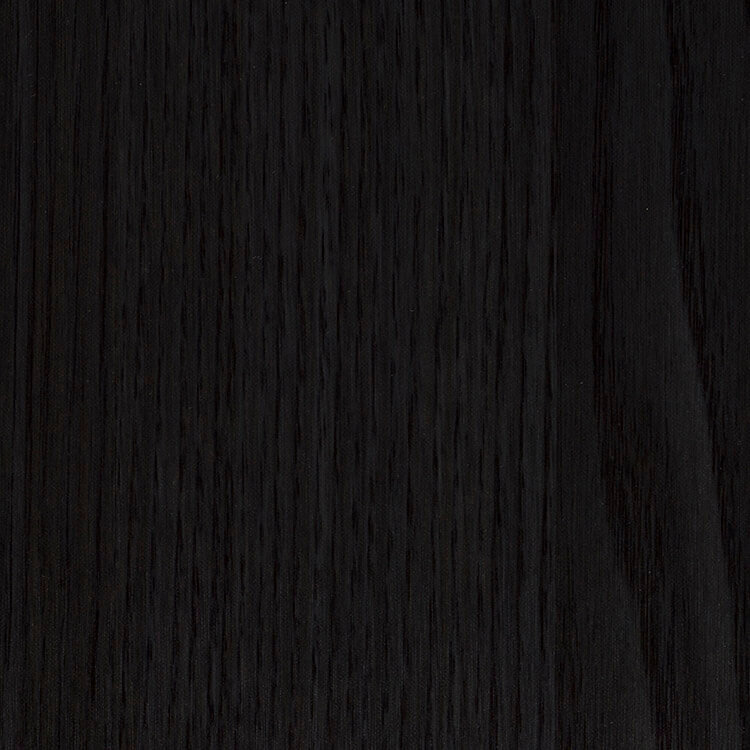

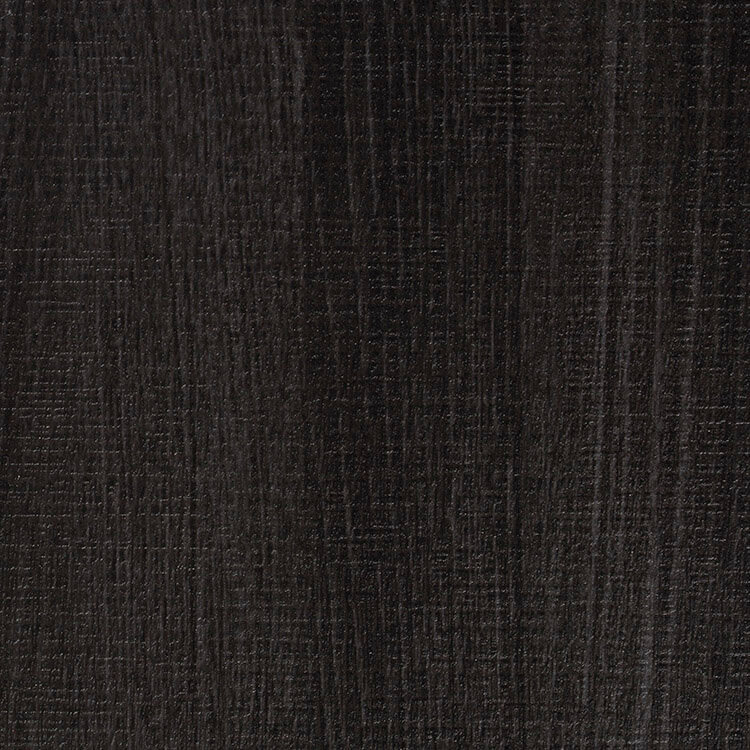

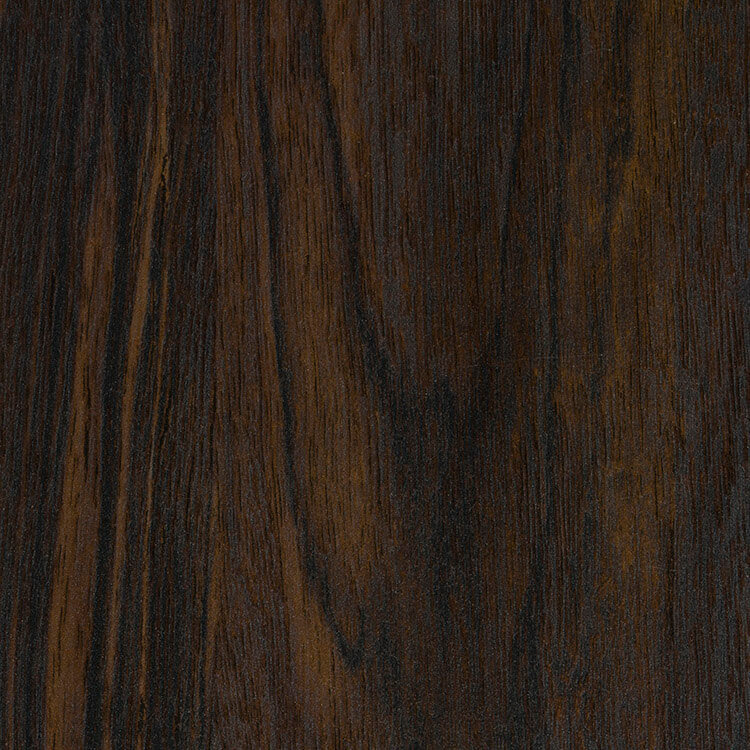

Covet Ever Art Wood® is an aluminium batten and panel cladding series with 0.2mm exterior grade polymer film applied to create realistic timber finishes. The Ever Art Wood® range has a more matte finish than powder coated options, generating a lower LRV, and the option of textured finishes further reduces light reflectance.

Ever Art Wood® is incredibly durable, as evidenced by Xenon Arc Tests, and registering minimal change in colour and appearance even after being subjected to the equivalent of 10-12 years weathering in a weatherometer. Covet Ever Art Wood® offers a low maintenance, dimensionally accurate, lightweight alternative to timber and steel. In addition to its incredible durability and aesthetic appeal, it comes in a range of low-LRV finishes - the majority of which fall within council reflectivity guidelines for external façade use. The full range of Covet Ever Art Wood® finishes was recently tested in accordance with BS 8493-2008 + A1-2010 - the results are included in Figure 1 below.

Test Result (CIE Tristimulus Value Y – Mean Results)

Standard: BS 8493-2008 + A1-2010

Testing Origin: AWTA Melbourne, Australia NATA certified lab

Figure 1: LRV test results for Covet Ever Art Wood® samples

As the results show, the low LRV properties of the Covet Ever Art Wood® range make it highly suitable for exterior façades. It also works well for interior applications, with strikingly realistic finishes that can provide a seamless transition between inside and out.

Specifiers are becoming increasingly concerned with the LRV properties of materials for external façades. With a growing number of councils and regulators adopting standards that recognise the importance of low-reflectivity materials in the urban environment, this is now also becoming a compliance issue. With a wide range of low-LRV wood and metal textures and finishes, Covet Ever Art Wood® aluminium battens and panels provide a durable, easy-to-install and visually appealing material suitable for use across a range of projects and applications. Specifiers on the hunt for a versatile material with low LRV would be well-placed to consider Covet Ever Art Wood® for their next project.